Tech Corner: A Beginner’s Guide to Pressure Sensitive Adhesives

What would happen if all the pressure sensitive adhesives – and the tape products they support – suddenly vanished off the face of the Earth?

A lot more than you might think. While the average consumer might only associate pressure sensitive adhesives (or PSAs for short) with products they find in the stationary sections of local retailers, manufacturers and logistics specialists understand how incredibly valuable PSAs are to their processes and products. If every PSA on the planet disappeared in a flash, cars, boats, airplanes, and even buildings around the world would fall to pieces because PSAs are a cost-effective, easy-to-use bonding agent used in varied applications at home, in retail and throughout industries.

In logistics and packaging, PSA tapes don’t just seal boxes closed. Many innovative PSA products are specially designed to relay important information to the recipient, like whether a package was tampered with, dropped or exposed to adverse environmental conditions like heat, cold or water.

Without PSAs, it would be more difficult to mount your photographs in an album or provide emergency repairs on that leaky hose! We would all go back to licking stamps! Think about how easy it is to ship that holiday or birthday gift to someone special. The packing tape uses a PSA, as does the address label. If you purchase a decorative sticker for the outside, guess what? That’s a PSA, too!

We could go on and on, but instead of listing off all the issues we’d face without PSAs, let’s talk about what PSAs are and all the different benefits they offer users.

“PSAs stick to a surface when users apply pressure to them.”

What are pressure sensitive adhesives?

As the name suggests, PSAs are a type of adhesive that stick to a surface when users apply pressure to them. If you’ve ever used craft tapes, stickers or decals, you’re already familiar with PSAs. Although these consumer-facing tape products represent a fraction of PSAs on the market today, they do adequately demonstrate a couple of the advantages their more industrial counterparts deliver to OEMs and other businesses.

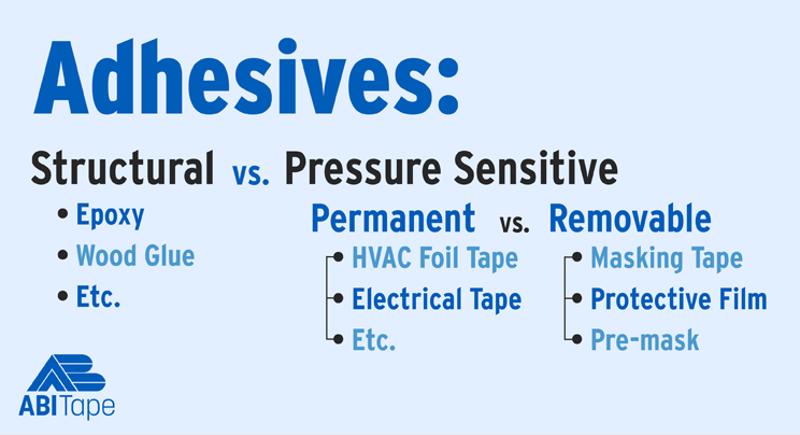

For starters, let’s look at the simple block diagram below. We’ll expand on that as we continue our journey. PSAs can be broadly classified as either removable or permanent. Removable PSAs must balance expectations for low peel products – like ease of removal with no residue – with a strong bond that still gets the job done.

On the other end of the spectrum, you have higher peel, higher tack PSA tapes designed for permanent applications. HVAC tapes used for sealing ductwork are a perfect example of permanent PSAs. The automotive industry also utilizes permanent PSAs to affix car components together as a way to reduce operating costs, maintain a high standard of quality and lighten car weights for greater fuel efficiency.

Why chemistry matters in PSAs

PSAs divide into many different classes, each containing unique ingredients. PSAs can either be water-based or solvent-based, as well as derived from from acrylic, rubber or silicone. But why so much variety? Don’t all these tapes serve the same, if not similar, purposes?

Sure, all tape holds things together to one degree or another, but an individual PSA’s chemistry may be better suited for certain applications over others depending on its properties and the properties of the substrates it bonds to. Manufacturers may require PSAs that are chemically compatible with specific kinds of surfaces. Moreover, OEMs may also need PSAs capable of withstanding certain conditions inherent in the manufacturing process or how consumers will use the product. PSAs can be engineered to many things, including but not limited to:

- Function outdoors

- Function over long durations

- Resist water

- Resist extreme heat

- Resist extreme cold

- Resist chemicals

- Withstand mechanical forces

Why ABI Tape cares about its PSAs

The diversity of end uses for permanent and removable PSA tape products only highlights the need for OEMs, logistics providers and other organizations to partner with tape specialists who understand the finer points in customization. ABI Tape offers a vast catalogue of PSA products, each scientifically designed to address needs specific to your industry and your one-of-a-kind application requirements. For more information on our PSA products, please contact your nearest ABI Tape representative or visit our website.