Celebrating 40 Years of ProtectRite®: A Legacy of Surface Protection

Celebrating 40 Years of ProtectRite®: A Legacy of Surface Protection

For four decades, ProtectRite has been at the forefront of surface protection, offering industry-leading solutions designed to safeguard materials during fabrication, transportation, and installation. As we celebrate 40 years of ProtectRite, we reflect on our journey, the innovations that have shaped our product line, and the continued commitment to excellence that defines our brand.

The Origins of ProtectRite

ProtectRite was founded on a simple yet essential principle: providing high-quality protective films to ensure surfaces remain pristine throughout the manufacturing and handling process. After 75 successful years in the industry, ABI expanded into the protective film market. Leveraging the expertise in adhesive solutions, we expanded our rubber-based product line to include acrylic adhesives under the ProtectRite brand in 1985. Since our inception in 1985, ProtectRite has been proudly union-made, reinforcing our commitment to quality craftsmanship and supporting workers. Over the years, we have worked closely with industries ranging from automotive and aerospace to construction and signage, tailoring our solutions to meet evolving demands.

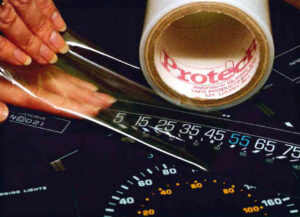

Our first ProtectRite products were 7301, 7303, 7305, and 7312 which offered a range of adhesion levels that could be used to protect surfaces such as vinyl graphics, smooth plastics, and anodized metals. Among them, 7301 led the way and represented the largest sales volume at the time and is still one of our top sellers.

At the time, every company that had a water-based coater jumped into the surface protection market–but while many have faded, ABI and the ProtectRite brand has stood the test of time. Forty years later, we’re still here, stronger than ever.

As demand grew, so did our innovation. We expanded our offering, introducing new tack levels and colors to meet diverse industry needs. A year later, we pushed boundaries again with higher tack solutions like 7316, 7318, 7322, and 7325, designed for textile applications such as carpets and upholstery. Water-based adhesives were the future, and we didn’t just embrace it—we went all in. We expanded our team from two chemists to five, all working on a single coater, dedicated to pioneering the next generation of surface protection.

Surface protection wasn’t just about film—it extended to paper as well. In 1988, we introduced 6926, a heavy-weight protective solution designed specifically for the aerospace industry. Engineered to safeguard polycarbonate windows and canopies, 6926 set the standard for durability and reliability in demanding environments. Since then, we have introduced various other paper masking solutions, including 6560, 6582, 6760 further enhancing our ability to protect a variety of surfaces such as, matte textured and satin finished plastics, fiberglass, and acrylic sheeting.

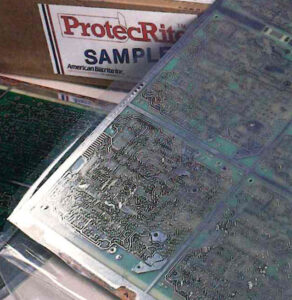

In the early 2000s, as we entered a new century, we expanded our ProtectRite brand to introduce state-of-the-art solvent rubber products—the 8500 Series. This lineup, featuring 8502, 8510, and 8514, was specifically engineered for premium painted and metal surfaces, delivering exceptional protection and performance.

Within the past few years, we have further expanded our ProtectRite line to include solvent natural rubber products–the 8600 series. This includes 8607, a high-performance fabrication product, 8627 a black and white protective film, and 8613, our innovative LaserRite DUO.

A Product for Every Protection Need

For 40 years, ProtectRite has been the trusted name in surface protection, and our products continue to set the standard. Whether shielding painted surfaces, metals, glass, or plastics, our protective films provide unbeatable performance with easy application and residue-free removal. Amongst our most celebrated solutions are:

- ProtectRite 8510 – One of our top-selling solutions, providing exceptional protection for high-gloss and polished surfaces. With excellent UV resistance, it’s perfect for outdoor applications.

- ProtectRite 7301 – A customer favorite for its reliability and versatility in various industrial applications, as both an intermediate and final surface protection film.

- ProtectRite 8607 – Engineered for specialty metal applications that have intricate fabrication requirements.

With an ever-expanding lineup, ProtectRite remains the first choice for industries that demand top-tier protection.

Why ProtectRite?

At ABI, we don’t just manufacture protective films—we create solutions that empower industries and protect their craftsmanship. Here’s why customers continue to choose ProtectRite:

- Unmatched Technical Support – Our experts are here to guide you every step of the way, ensuring you get the right protection for your needs. We have expanded our sales team to include a Business Unit Director, a Product Manager, two Territory Managers, in addition to our dedicated customer service team.

- Made in the USA – For over 100 years, ABI has been proudly manufacturing in North America, ensuring superior performance and reliability.

- Union strong – Since day one, ProtectRite has been proudly union-made, reinforcing our dedication to craftsmanship and fair labor.

- Constant Innovation – We never stop pushing the boundaries, continuously expanding our product line, and breaking into new markets to protect more surfaces and meet evolving industry demands.

Looking Ahead

As we mark 40 years of ProtectRite, we celebrate not just our past but our future. Our journey has been defined by innovation dedication, and a relentless pursuit of excellence. We’re not slowing down—we’re gearing up for the next 40 years and beyond.

Our slogan says it best: “You make it perfect, we’ll keep it perfect.”

Thank you for being part of the ProtectRite legacy. Here’s to 4 decades of protection—and many more to come!